Lithography is a fascinating printmaking process based on surface chemistry principles. You create images using greasy materials on a flat stone surface, which attract ink while water keeps non-image areas ink-free. Controlling oil and water interactions allows you to produce detailed, sharp prints. This technique combines art and science to make reproductions that are both precise and expressive. Keep exploring, and you’ll discover how mastering these chemical tricks brings lithography’s magic to life.

Key Takeaways

- Lithography uses a greasy image on a flat stone surface to attract ink while water repels it, creating a printable image.

- The process relies on surface chemistry, controlling interactions between grease, water, and ink for precise image transfer.

- Artists draw with greasy materials, then treat the stone to develop areas that attract ink and repel water in the printing process.

- Proper surface preparation and chemical control enable detailed, consistent prints through careful ink application and pressing.

- Modern innovations combine traditional lithography with digital and eco-friendly techniques, enhancing precision and sustainability.

How Did Lithography Start? A Brief History

Lithography began in the late 18th century as a new printing technique that revolutionized image reproduction. Its historical origins trace back to Alois Senefelder, who developed the process in 1796 to simplify printing. This method quickly gained cultural significance, especially in art and publishing, because it allowed artists and printers to produce detailed images efficiently. Unlike earlier techniques, lithography used a flat stone surface and greasy substances to create images, making it more accessible and versatile. The development of pencil and ink techniques further enhanced its capabilities, allowing for greater detail and precision. As it spread across Europe, it influenced visual culture and democratized art reproduction. Today, lithography remains an essential part of artistic and commercial printing, but its roots in innovation and cultural importance continue to shape its legacy. The use of chemical processes in lithography also played a crucial role in refining image quality and expanding its applications. Additionally, the integration of industrial advancements helped scale lithography for mass production, solidifying its importance in printing history. Moreover, the evolution of materials and chemicals contributed to the technique’s adaptability and improved durability over time. The ongoing advancements in printing technology have further extended lithography’s relevance in modern manufacturing and art.

What Are the Key Ideas Behind Lithography?

Have you ever wondered how detailed images are reproduced so accurately in lithography? The key ideas rely on controlling surface tension and chemical reactions on the stone’s surface.

First, you coat the surface with a greasy substance that attracts ink but repels water. When you apply a water-based solution, it interacts with the grease through chemical reactions, making certain areas hydrophilic and others hydrophobic. Surface chemistry plays a crucial role in optimizing lithographic techniques and achieving high-quality prints. This understanding of surface interactions allows artisans to manipulate the process for better precision. It’s also important to consider how substance behavior influences the final image quality and durability. Additionally, controlling the surface energy of the stone’s surface enables more consistent results across different materials and conditions.

Coating the surface with grease creates areas that attract ink and repel water through chemical reactions.

Surface tension helps keep the water and ink separate, so only the greasy image areas pick up ink. This delicate balance allows precise transfer of images onto paper or other materials. Additionally, understanding the behavior of substances on the surface enables artists and technicians to fine-tune the process for better results. Enhancing this knowledge can lead to innovations in printing technology and more durable images.

The process hinges on understanding how substances behave on the surface, ensuring the image remains clear and detailed through the interaction of surface tension and chemical reactions.

How Do Oil, Water, and Grease Make Lithography Work?

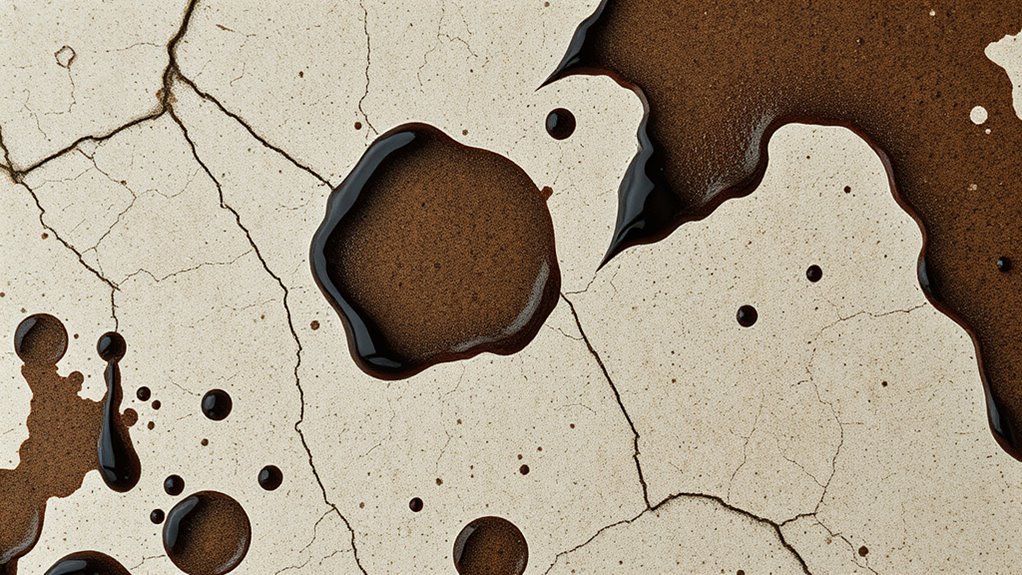

Ever wonder how oil, water, and grease work together to create detailed images in lithography? It all comes down to the oil water interaction. When you apply grease to the stone, it sticks well because of grease adhesion, forming the image areas. The greasy parts repel water, so they don’t get washed away. Conversely, the water adheres to the blank areas, preventing ink from sticking there. This delicate balance allows the greasy image to resist water, while the water keeps the non-image areas ink-free. This oil-water interaction creates a clear contrast between the image and non-image regions. The precise control over grease adhesion and water repellence is what enables lithography to produce such detailed and accurate prints. Understanding lithography’s mechanics helps explain how these interactions achieve such precision, especially through the use of hydrophobic and hydrophilic surfaces.

How Is a Lithograph Made? A Step-by-Step Guide

To create a lithograph, you start by preparing the stone surface to guarantee it’s smooth and clean. Next, you draw your image on the stone using a greasy substance that will resist water. Proper surface preparation is essential to ensure the quality of the print and prevent mistakes during the printing process. Finally, you apply ink and press the stone onto paper to produce your print.

Preparing the Stone Surface

Before you can begin drawing on the stone, you’ll need to prepare its surface properly. Start with stone preparation by cleaning it thoroughly to remove any dirt, oil, or debris that could interfere with the process. Use a damp cloth or a gentle abrasive if needed, but avoid rough scrubbing. Ensuring the surface is free of contaminants is crucial for effective home‑care techniques and achieving optimal results. Once the surface is clean and dry, apply a thin, even layer of grease using a brush or roller. This grease application creates a smooth, receptive surface for your drawing materials and guarantees proper ink adherence later. Be careful to cover the entire area uniformly, avoiding thick or uneven layers. Proper stone preparation and precise grease application are vital steps to achieve a successful lithograph, setting the foundation for your artwork to come to life. Additionally, understanding the chemical properties of the materials involved can help you better control the process and ensure consistent results. For example, the fiber content of the stone can influence how well the grease bonds and how evenly the ink adheres during printing. Recognizing the material composition of the stone can also help prevent unexpected issues during the printing process.

Drawing the Image With Grease

Once the stone surface is prepared and smooth, you can begin drawing your image with grease. Use grease application carefully, applying it only where you want ink to adhere. Traditional drawing techniques involve using lithographic crayons, tusche, or brushes dipped in greasy ink to sketch your design directly onto the stone. Focus on creating bold, confident lines, as fine details may be harder to control. Remember, grease repels water but attracts ink, so your drawing must be precise. You can also utilize shading techniques by varying the pressure or layering grease. Take your time to develop the image, ensuring the greasy marks are clear and consistent. This step is essential for transferring your design accurately during printing. Proper technique in applying grease is crucial for achieving high-quality lithographs, especially when considering water and ink interactions during the process. Mastering the fundamentals of lithography ensures better control over the entire process, leading to more consistent results. Understanding the chemistry involved in these interactions can greatly improve your success in creating detailed and accurate prints. Additionally, practicing test prints can help refine your approach before producing final works.

Printing the Final Image

After your design is complete on the stone, the next step is to transfer it onto the printing surface through a process called etching. You apply ink to the stone, guaranteeing it sticks only to the greasy image areas.

Then, you press a dampened sheet of paper onto the inked stone, using a press to facilitate ink transfer. This pressure allows the ink to bond accurately with the paper, preserving the image fidelity you created.

Proper pressure and even distribution are essential to produce sharp, detailed prints. Once the paper is lifted, you’ll see the final image, clear and true to your original design.

Repeating this process for multiple copies ensures consistent quality, capturing the nuances of your artwork through precise ink transfer.

What Are Today’s Cool Uses and New Tricks in Lithography?

Have you ever wondered how lithography is pushing boundaries today? One exciting development is its integration with digital printing, which allows for faster, more precise production of images and designs. This technique offers greater flexibility, enabling artists and businesses to create customized prints with ease. Smart home technology innovations are also inspiring new approaches to industrial processes, including lithography, by incorporating automation and adaptive systems. Additionally, modern lithography now uses eco-friendly inks, reducing environmental impact without sacrificing quality. These inks are biodegradable and less toxic, making the process safer for printers and the planet. The adoption of sustainable materials in lithography further enhances its eco-conscious footprint, paving the way for greener manufacturing practices. Such innovations open new doors for sustainable art, packaging, and commercial printing. Companies are also experimenting with new materials and techniques to achieve sharper details and vibrant colors. Overall, today’s lithography combines traditional craftsmanship with cutting-edge technology, making it more versatile and environmentally conscious than ever before.

How Can You Master the Art and Science of Lithography?

Mastering the art and science of lithography requires a blend of technical skill and creative insight. To do this, you need to understand how chemical reactions work on the stone or plate, allowing you to control which areas attract ink and which repel it.

Practice applying artistic techniques, like sketching and shading, to develop your eye for detail and composition. Experiment with different materials and chemical processes to see how they influence your prints.

Study classic works and learn how master lithographers combined science with artistic expression. By honing your skills in both areas, you’ll gain confidence in creating consistent, high-quality images while exploring innovative methods to push your artistic boundaries.

Frequently Asked Questions

Can Lithography Be Used for Digital Printing Processes?

Yes, lithography can be adapted for digital printing processes. While traditional lithography uses plates and chemicals, modern techniques like inkjet technology mimic lithographic principles by using tiny nozzles to deposit ink directly onto surfaces.

You can leverage digital printing for high-quality images, combining lithography’s detailed image transfer with the speed and flexibility of inkjet technology, making it suitable for various applications like posters, packaging, and fine art reproductions.

What Are Common Materials Used as Lithographic Stones Today?

You’ll find that modern lithographic stones are often made from limestone or synthetic materials designed to mimic traditional stones. These lithographic stones, such as fine-grained limestone, are favored for their durability and ability to hold ink.

Some artists and printers also use advanced materials like aluminum plates or polymer-based substrates, offering a lightweight and cost-effective alternative. These materials help streamline the printing process while maintaining the quality of traditional lithography.

How Has Lithography Impacted Modern Semiconductor Manufacturing?

You see, lithography has revolutionized modern semiconductor manufacturing through photolithography advancements, enabling precise semiconductor patterning at tiny scales.

These innovations allow you to create increasingly complex and smaller microchips, boosting performance and efficiency.

Are There Environmental Concerns Associated With Traditional Lithography?

Yes, traditional lithography poses environmental concerns. You should know that it generates chemical waste from the use of solvents and photoresists, which can harm ecosystems if not properly managed.

The process also consumes significant amounts of energy, contributing to the environmental impact. To minimize these issues, manufacturers are adopting greener chemicals and more efficient techniques, helping reduce chemical waste and lessen the overall environmental footprint of semiconductor production.

What Are the Main Challenges Faced by Contemporary Lithographers?

You face challenges like ensuring chemical resistance and maintaining image stability in contemporary lithography.

As materials evolve, you must adapt to resist chemicals used in etching and development processes, preventing damage to your images.

Achieving consistent image stability is vital for high-quality prints, requiring precise control of process parameters.

These hurdles demand innovation and careful material selection, pushing you to improve techniques and stay ahead in the competitive field of lithography.

Conclusion

Now that you know how lithography works, you can appreciate its blend of art and science. From its ancient origins to modern innovations, lithography continues to evolve, offering exciting possibilities. With practice and curiosity, you can master this fascinating technique, creating stunning prints and exploring new creative directions. So go ahead—dive into the world of lithography and discover your own stone-and-grease magic trick!