If you’re searching for the 12 best mounting press machines for 2026, I’ve got you covered. From versatile hydraulic presses with movable plates, high-precision heat press models, to manual arbor presses perfect for small jobs, there’s a wide range to choose from. Each machine offers unique features like adjustable pressure, safety mechanisms, and durable construction. Keep going, and you’ll discover detailed insights to help you pick the perfect press for your needs.

Key Takeaways

- Evaluate press machines based on capacity, material compatibility, and adjustability for diverse mounting tasks.

- Prioritize safety features like relief valves, guards, and automatic shut-offs for secure operation.

- Consider multi-function and specialty presses such as heat press and arbor presses for versatility.

- Focus on durable construction with high-quality materials like cast iron and alloy steel for longevity.

- Review models with user-friendly controls, compact design, and positive customer feedback for reliability.

| VEVOR 6 Ton Hydraulic Shop Press with Movable Plates |  | Heavy-Duty Performance | Capacity: 6 Ton | Max Working Height: 2.2–9.8 inches | Adjustable Height: Yes, pin system | VIEW LATEST PRICE | See Our Full Breakdown |

| Dual Workbench Auto Heat Press Machine with Swing Away |  | High-Volume Efficiency | Capacity: Not specified (large heat plate) | Max Working Height: 1.85 inches | Adjustable Height: Yes | VIEW LATEST PRICE | See Our Full Breakdown |

| Dual Workbench Heat Press with Auto Features |  | Automatic Convenience | Capacity: Not specified (large heat plate) | Max Working Height: 1.85 inches | Adjustable Height: Yes | VIEW LATEST PRICE | See Our Full Breakdown |

| Horgelu 5-in-1 15×15 Heat Press Machine |  | Multifunctional Flexibility | Capacity: Not specified (large heat plate) | Max Working Height: 1.85 inches | Adjustable Height: Yes | VIEW LATEST PRICE | See Our Full Breakdown |

| 6 Ton Hydraulic Press Machine with Movable Plate |  | Industrial Strength | Capacity: 6 Ton | Max Working Height: 2.2–9.8 inches | Adjustable Height: Yes, pin system | VIEW LATEST PRICE | See Our Full Breakdown |

| Upgraded Hot Foil Stamping Machine for Leather and PVC |  | Precision Embossing | Capacity: Not specified (small heat plate) | Max Working Height: Not specified | Adjustable Height: Not specified | VIEW LATEST PRICE | See Our Full Breakdown |

| KAKA Industrial 2-Ton Arbor Press Adjustable Height |  | Robust Power | Capacity: 2 Ton | Max Working Height: 8 inches | Adjustable Height: Yes | VIEW LATEST PRICE | See Our Full Breakdown |

| Manual Cylinder Screen Printing Machine with Brackets |  | Versatile Applications | Capacity: Not specified (small to medium objects) | Max Working Height: Not specified | Adjustable Height: Not specified | VIEW LATEST PRICE | See Our Full Breakdown |

| TUFFIOM 6Ton Hydraulic Shop Press with Press Plates |  | Reliable Durability | Capacity: 6 Ton | Max Working Height: Not specified | Adjustable Height: Not specified | VIEW LATEST PRICE | See Our Full Breakdown |

| 3-Ton Manual Arbor Press for Stamping and Bending |  | Compact Powerhouse | Capacity: 3 Ton | Max Working Height: 12.2 inches | Adjustable Height: Yes | VIEW LATEST PRICE | See Our Full Breakdown |

| Arbor Press 1 Ton with Hand Wheel Cast Iron |  | Space-Saving Strength | Capacity: 1 Ton | Max Working Height: 5.9 inches | Adjustable Height: Yes | VIEW LATEST PRICE | See Our Full Breakdown |

| 2 Ton Cast Iron Arbor Press with Hand Wheel |  | Precision Control | Capacity: 2 Ton | Max Working Height: 8.5 inches | Adjustable Height: Yes | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

VEVOR 6 Ton Hydraulic Shop Press with Movable Plates

If you’re looking for a reliable, versatile press that handles both automotive repairs and metalworking tasks, the VEVOR 6 Ton Hydraulic Shop Press with Movable Plates is an excellent choice. Its heavy-duty H-shaped frame provides stability, ensuring smooth operation without wobbling. Made from durable 0.1-inch carbon steel with a corrosion-resistant finish, it’s built to last. The adjustable height (2.2 to 9.8 inches) and movable stamping plates make it flexible for various projects. Equipped with a safety relief valve and a hydraulic jack, it prioritizes user security. Whether you’re a professional or DIY enthusiast, this press delivers quick, efficient results.

- Capacity:6 Ton

- Max Working Height:2.2–9.8 inches

- Adjustable Height:Yes, pin system

- Swing-away:No

- Safety Features:Relief valve, corrosion-resistant

- Construction Material:Carbon steel

- Additional Feature:Movable stamping plates included

- Additional Feature:Powder-coated corrosion resistant finish

- Additional Feature:Adjustable pin height system

Dual Workbench Auto Heat Press Machine with Swing Away

The Dual Workbench Auto Heat Press Machine with Swing Away stands out as an ideal choice for those seeking high efficiency and versatility in their heat pressing projects. It offers two configurations—Single and Dual Workstation—perfect for different workspace sizes and production needs. The large 15×15 inch heating plate handles a variety of applications like HTV, sublimation, and heat transfer. With automatic press and release, a 360° swing-away design, and adjustable pressure levels, it guarantees safety and precision. Built with premium components and user-friendly features, this machine is well-suited for both home and light commercial use, making it a smart investment.

- Capacity:Not specified (large heat plate)

- Max Working Height:1.85 inches

- Adjustable Height:Yes

- Swing-away:Yes

- Safety Features:Automatic shut-off, audible beep

- Construction Material:Steel, powder-coated

- Additional Feature:7 pressure levels

- Additional Feature:Automatic press/release

- Additional Feature:360° swing-away design

Dual Workbench Heat Press with Auto Features

A dual workbench heat press with auto features is an excellent choice for those who need to boost productivity and guarantee consistent results across large batches. I find that the dual configuration allows for rapid processing, making it perfect for high-volume projects. Its automatic pressure application and release simplify operation, saving time and reducing user fatigue. The 15×15 inch heating plate accommodates various materials, while adjustable pressure levels ensure ideal results. The swing-away arm provides safe, full access to the work surface, and safety features like automatic shut-off enhance peace of mind. Overall, this press combines efficiency, safety, and versatility, making it a top contender for 2026.

- Capacity:Not specified (large heat plate)

- Max Working Height:1.85 inches

- Adjustable Height:Yes

- Swing-away:Yes

- Safety Features:Automatic shut-off, audible beep

- Construction Material:Steel, powder-coated

- Additional Feature:15×15 inch heating plate

- Additional Feature:Automatic pressure adjustment

- Additional Feature:Practice DTF set included

Horgelu 5-in-1 15×15 Heat Press Machine

Designed for versatility and ease of use, the Horgelu 5-in-1 15×15 Heat Press Machine stands out as an excellent choice for both beginners and professionals. It features five interchangeable attachments, including a large Teflon-coated platen, curved cap press, mug press, and two plate presses, making it suitable for T-shirts, mugs, plates, and hats. The advanced 2025 control panel allows precise temperature and time adjustments, with simple operation and audible alerts. Safety is prioritized with a swing-away design, insulated cover, and circuit protectors. Its durable heating plate guarantees quick, even heat, delivering high-quality results across various materials and applications.

- Capacity:Not specified (large heat plate)

- Max Working Height:1.85 inches

- Adjustable Height:Yes

- Swing-away:Yes

- Safety Features:Automatic shut-off, safety clamp

- Construction Material:Steel, powder-coated

- Additional Feature:Five interchangeable attachments

- Additional Feature:Digital control panel

- Additional Feature:Insulated safety cover

6 Ton Hydraulic Press Machine with Movable Plate

If you’re looking for a versatile hydraulic press that can handle small parts with precision, the 6-ton hydraulic press with a movable plate is an excellent choice. It offers a 6-ton (13,000 lbs) capacity, perfect for tasks like removing bushings, bearings, and gears. The adjustable height settings from 2.2 to 9.8 inches, combined with dual movable stamping plates, ensure secure and accurate pressing. Built with a sturdy H-frame and corrosion-resistant powder coating, it’s durable and stable. Safety features like a built-in relief valve prevent overloads, making it suitable for both professional workshops and DIY projects.

- Capacity:6 Ton

- Max Working Height:2.2–9.8 inches

- Adjustable Height:Yes, pin system

- Swing-away:Yes

- Safety Features:Relief valve, corrosion-resistant

- Construction Material:Steel, powder-coated

- Additional Feature:Reinforced carbon steel body

- Additional Feature:Dual movable stamping plates

- Additional Feature:Quick pin height adjustment

Upgraded Hot Foil Stamping Machine for Leather and PVC

The Upgraded Hot Foil Stamping Machine for Leather and PVC stands out with its precise full-scale base plate and adjustable mold mounting slot, making it ideal for craftsmen and small businesses aiming for accurate, high-quality embossing. Its compact size and digital display simplify operation, while four high-elasticity balance springs ensure even pressure for consistent results. The long mold mounting slot allows easy installation and adjustment, accommodating various materials. With adjustable temperature and pressure settings, it’s versatile for leather, PVC, PU, and paper. Plus, it comes with practice foil in silver and gold, helping you perfect your designs with ease.

- Capacity:Not specified (small heat plate)

- Max Working Height:Not specified

- Adjustable Height:Not specified

- Swing-away:Yes

- Safety Features:Safety circuit protectors

- Construction Material:Cast aluminum, silicone

- Additional Feature:Full-scale base plate

- Additional Feature:Silver/gold foil included

- Additional Feature:Adjustable pressure/temperature

KAKA Industrial 2-Ton Arbor Press Adjustable Height

For anyone needing precise force application in small-scale projects, the KAKA Industrial 2-Ton Arbor Press with adjustable height stands out as a versatile choice. It delivers a 2-ton (4,400 pounds) pressing force, perfect for bearing installation, bushing removal, and shaping small parts. The ram height can be adjusted up to 8 inches, allowing for flexible handling of various workpieces. Built with high-quality steel and a sturdy base, it ensures durability and stability. Operated manually with a lever, it offers precise control and safer operation. Its compact, lightweight design makes it ideal for limited workspace, garages, or DIY setups.

- Capacity:2 Ton

- Max Working Height:8 inches

- Adjustable Height:Yes

- Swing-away:No

- Safety Features:Manual operation, stable frame

- Construction Material:Steel, durable finish

- Additional Feature:Adjustable ram height

- Additional Feature:Manual lever operation

- Additional Feature:Compact portable design

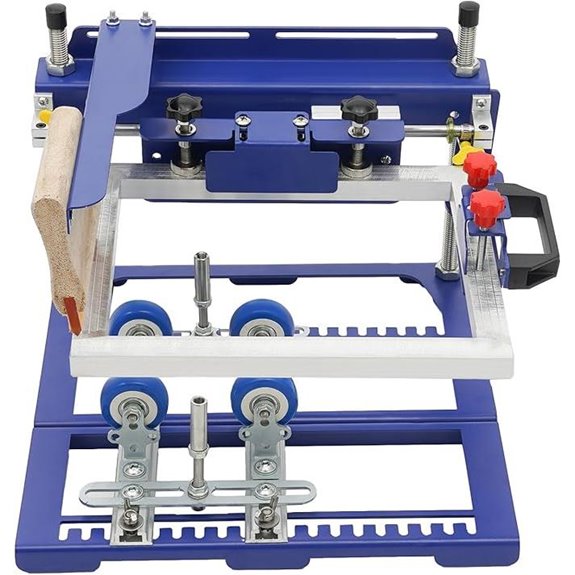

Manual Cylinder Screen Printing Machine with Brackets

A standout feature of the Manual Cylinder Screen Printing Machine with Brackets is its adjustable height, which allows for precise positioning on cylindrical and conical objects up to 170mm in diameter. With a 200mm range via the post screw, I can easily tailor the setup for different products. It supports items up to 200mm in height and 150mm in pattern length, making it versatile for various small to medium-sized objects like bottles, mugs, and glassware. The machine’s left-right push-pull structure and adjustable brackets guarantee smooth operation, stability, and consistent printing quality on a wide range of materials, including plastic, glass, and metal.

- Capacity:Not specified (small to medium objects)

- Max Working Height:Not specified

- Adjustable Height:Not specified

- Swing-away:Yes

- Safety Features:Adjustable, stable mount

- Construction Material:Cast iron, steel components

- Additional Feature:Adjustable height post screw

- Additional Feature:Wide object compatibility

- Additional Feature:Bracket mounting included

TUFFIOM 6Ton Hydraulic Shop Press with Press Plates

If you’re looking for a durable and versatile hydraulic press for small shop or garage tasks, the TUFFIOM 6-Ton Hydraulic Shop Press with Press Plates stands out with its sturdy H-frame design and adjustable features. Made from alloy steel and powder-coated for corrosion resistance, it offers durability and easy cleaning. Its adjustable working table with multiple height options allows for customization, while the simple handle operation makes pressing straightforward. With a 6-ton capacity, it’s perfect for bending and straightening metal. Compact yet robust at 50.7 pounds, it provides stability during use and is ideal for small-scale industrial or garage applications.

- Capacity:6 Ton

- Max Working Height:Not specified

- Adjustable Height:Not specified

- Swing-away:No

- Safety Features:No specific safety features listed

- Construction Material:Alloy steel

- Additional Feature:Powder-coated finish

- Additional Feature:Four-position worktable

- Additional Feature:Simple hydraulic operation

3-Ton Manual Arbor Press for Stamping and Bending

The Ton Manual Arbor Press stands out as an ideal choice for professionals seeking reliable, high-capacity pressing and bending solutions. With a 3-ton force capacity and a 12.2-inch maximum working height, it handles tasks like riveting, extrusion, punching, and bending with ease. Made from durable cast iron and featuring a carbon steel structure, it offers stability and strength for demanding work. The reversible ram and removable steel anvil provide versatility for shaping metals and plastics. Its compact design, reinforced base, and pre-drilled mounting holes make it perfect for workshops with limited space, ensuring reliable performance in various manufacturing and maintenance applications.

- Capacity:3 Ton

- Max Working Height:12.2 inches

- Adjustable Height:Yes

- Swing-away:Yes

- Safety Features:Manual with safety features

- Construction Material:Cast iron, steel

- Additional Feature:Reversible ram

- Additional Feature:Fine-tuned vise

- Additional Feature:Compact footprint

Arbor Press 1 Ton with Hand Wheel Cast Iron

For those seeking a durable and precise manual pressing solution, the Arbor Press 1 Ton with Hand Wheel made of cast iron stands out as an excellent choice. It delivers up to 1 ton of pressure within a compact design, making it ideal for stamping, bending, and punching tasks. Its sturdy cast iron construction guarantees stability and reliability, while the reinforced base allows secure mounting. The hand wheel enables fine pressure adjustments, simplifying complex operations. Weighing just over 35 pounds, it’s portable yet robust enough for demanding work. This press is perfect for workshops with limited space, offering durability and control in a sleek blue finish.

- Capacity:1 Ton

- Max Working Height:5.9 inches

- Adjustable Height:Yes

- Swing-away:No

- Safety Features:No specific safety features listed

- Construction Material:Cast iron

- Additional Feature:Cast iron construction

- Additional Feature:Manual hand wheel

- Additional Feature:Pre-drilled mounting holes

2 Ton Cast Iron Arbor Press with Hand Wheel

A 2-ton cast iron arbor press with a hand wheel stands out as an ideal choice for those seeking precise control and reliable power in their pressing tasks. Made from high-quality cast iron with a sturdy carbon steel structure, it offers exceptional strength and stability for demanding operations. Its compact design, with an 8.5-inch working height, fits well in limited spaces. The thickened base with pre-drilled holes allows for secure mounting, enhancing stability during use. The easy-to-operate lever and fine-tuned vise reduce effort, making repetitive tasks more efficient. Perfect for riveting, punching, bending, or forming, this arbor press combines versatility with durability.

- Capacity:2 Ton

- Max Working Height:8.5 inches

- Adjustable Height:Yes

- Swing-away:No

- Safety Features:Pre-drilled mounting, stable base

- Construction Material:Cast iron, steel

- Additional Feature:Space-efficient design

- Additional Feature:Lever labor-saving

- Additional Feature:Sturdy pre-drilled base

Factors to Consider When Choosing a Mounting Press Machine

When selecting a mounting press machine, I focus on key factors like capacity and force to guarantee it meets my project needs. I also consider the size and available space, along with material compatibility and safety features for smooth operation. Finally, I look at adjustability options to make sure I can fine-tune the machine for different tasks.

Capacity and Force

Choosing the right mounting press hinges on understanding its capacity and force, which directly influence how effectively it handles your specific tasks. Capacity, measured in tons, indicates the maximum force the press can exert—usually from 1 to 6 tons or more. It’s vital to match this with your application, whether pressing bearings, bending metal, or stamping. Using a press beyond its rated capacity risks mechanical failure or damage, so selecting one with an appropriate safety margin is essential. Additionally, the force should be adjustable within a range, allowing precise control for different tasks. Knowing the maximum force needed helps guarantee consistent results and prevents equipment overload. Properly matching capacity and force guarantees efficiency, safety, and longevity for your mounting press.

Size and Space

Selecting the right mounting press requires carefully evaluating your workspace to guarantee it fits comfortably and allows for smooth operation. First, measure your available space to ensure the press’s footprint fits without overcrowding. Consider the size of the machine’s base and overall dimensions, making sure it suits your designated area. Don’t forget to account for extra clearance needed for safe operation, maintenance, and access around the machine. Check your ceiling height and access points to ensure there’s enough room for the press’s height and any swing-away features. Finally, choose a machine whose size aligns with your storage options and workflow layout, preventing clutter and ensuring efficient use of your workspace. Proper sizing is key to a safe, functional setup.

Material Compatibility

Ensuring your mounting press machine is compatible with the materials you plan to work with is essential for achieving ideal results and safety. I recommend checking if the machine can handle materials like leather, PVC, metal, or fabric, as each has different processing needs. Pay attention to maximum temperature and pressure ratings to match your material’s requirements for effective, safe mounting. The surface and base plate materials, such as cast aluminum or stainless steel, should be durable and provide even heat distribution. Also, consider whether the machine offers interchangeable attachments or molds suitable for various thicknesses and types of materials. Finally, a precise control system for adjusting temperature and pressure is crucial for tailoring settings to specific material specifications, ensuring quality and safety.

Safety Features

Safety features are crucial when evaluating mounting press machines because they directly impact both operator safety and machine reliability. Built-in relief valves prevent overpressure, safeguarding the operator and protecting the equipment from damage. Automatic shut-off mechanisms reduce risks by stopping the machine if it runs too long or if an issue arises unexpectedly. Safety guards and covers around hydraulic or mechanical parts minimize exposure to moving or hot surfaces, preventing injuries. Emergency stop buttons allow immediate power cut-off, ensuring quick response during emergencies. Additionally, sturdy construction with reinforced frames and secure mounting enhances overall safety, providing stability during operation. These features are essential for maintaining a safe working environment and minimizing accidents while maximizing machine performance.

Adjustability Options

When choosing a mounting press machine, considering its adjustability options is essential for achieving ideal performance and versatility. I look for machines with adjustable height settings, like pin systems or threaded mechanisms, to customize for different workpiece sizes. The adjustment range, typically from 2 to 10 inches, is critical for handling various applications. Movable or sliding plates help secure parts and make clamping easier, while features like swing-away arms or tilting plates optimize workspace access and safety during adjustments. Locking or quick-release mechanisms are indispensable to keep settings stable during operation. These features ensure the machine can adapt to different tasks efficiently, providing both precision and flexibility. Proper adjustability makes a significant difference in workflow and final results.

Durability and Build

Choosing a mounting press machine that’s built to last starts with examining the materials and construction quality. I look for high-strength materials like cast iron, steel, or alloys, which can handle heavy use without deforming. The build quality matters—welds, joints, and frame design should be solid to prevent wear, wobbling, or fatigue over time. Corrosion resistance features, such as powder coating or stainless steel parts, are vital, especially in moist environments, as they extend the machine’s lifespan. Reinforced bases and pre-drilled mounting holes ensure stability during operation, keeping safety and precision intact. Ultimately, a robust build not only boosts performance but also reduces maintenance costs, making it a smarter investment that will serve me reliably for years.

Frequently Asked Questions

What Safety Features Are Essential in a Mounting Press Machine?

Safety features are essential in a mounting press machine to prevent accidents and guarantee smooth operation. I look for emergency stop buttons that are easily accessible, safety guards that shield moving parts, and sensors that detect misalignments or overloads. Having clear safety instructions and proper training also helps. These features give me peace of mind knowing the machine is designed to protect me while I work efficiently.

How Energy-Efficient Are Modern Mounting Press Machines?

Modern mounting press machines are like well-tuned engines, running efficiently and conserving energy. They typically use advanced electronics and optimized hydraulic systems, which markedly reduce power consumption. I’ve noticed that newer models often feature smart technology that adjusts energy use based on workload, making them more eco-friendly. Overall, these machines aren’t just powerful—they’re designed to minimize energy waste, helping us save costs while protecting the environment.

Can Mounting Press Machines Be Customized for Specific Applications?

Absolutely, mounting press machines can be customized for specific applications. I’ve seen manufacturers tailor features like pressing force, bed size, and control systems to meet unique needs. Whether you require specialized tooling, adjustable pressure settings, or custom automation, these machines can often be altered. This flexibility ensures that I get the precise performance and efficiency I need for my particular projects, making them highly adaptable to various industries and tasks.

What Is the Typical Lifespan of a Quality Mounting Press Machine?

A quality mounting press machine can last a lifetime if well-maintained, like a trusty old friend who only gets better with age. Typically, you can expect 10 to 20 years of reliable service, but with proper care—regular lubrication, timely repairs, and cautious operation—it can serve even longer. Think of it as an investment that grows more valuable and dependable over the years, ready to meet your needs whenever you call on it.

Are There Maintenance Tips to Extend the Machine’s Durability?

Yes, there are maintenance tips I recommend to extend your mounting press machine’s durability. I regularly clean and lubricate moving parts, ensuring they stay smooth and free of debris. I also check for loose bolts and worn components, replacing them promptly. Additionally, I follow the manufacturer’s maintenance schedule and keep the machine in a clean, dry environment. These steps help me maximize its lifespan and keep it running efficiently.

Conclusion

In wrapping up, I hope this helps you hone in on your perfect press! Whether you’re seeking strength, speed, or specific features, remember to weigh your wants wisely. By considering capacity, convenience, and craftsmanship, you’ll confidently choose a machine that maximizes your mastery. With the right press, you’ll turn tedious tasks into triumphant triumphs, transforming your workspace into a well-oiled wonderland of work and wonder.