In screenprinting, layers matter more than just choosing the right colors because they add depth, detail, and realism to your designs. Each layer builds on the last, creating smooth gradients, sharp images, and vibrant hues. Proper layer order, registration, and management guarantee your prints stay clean and precise. Mastering layering speeds up production and improves quality. Keep exploring, and you’ll discover how to harness layers for truly professional prints.

Key Takeaways

- Layers add depth, realism, and visual interest, often more impactful than color alone.

- Proper layering ensures sharp, vibrant images with smooth gradients and seamless tone transitions.

- Managing layers improves stencil precision, reducing errors and reprints for higher quality results.

- Layers streamline workflow, save time, and promote consistency across multiple prints.

- Mastering layers enhances overall screenprint quality, allowing for complex and professional designs.

What Are Layers and Why Do They Matter in Screenprinting

Have you ever wondered how screenprints achieve their vibrant, detailed designs? The secret lies in understanding layers. Each layer adds a specific element to your final design, building complexity and depth.

Layers are the key to vibrant, detailed screenprints, adding depth and complexity to your design.

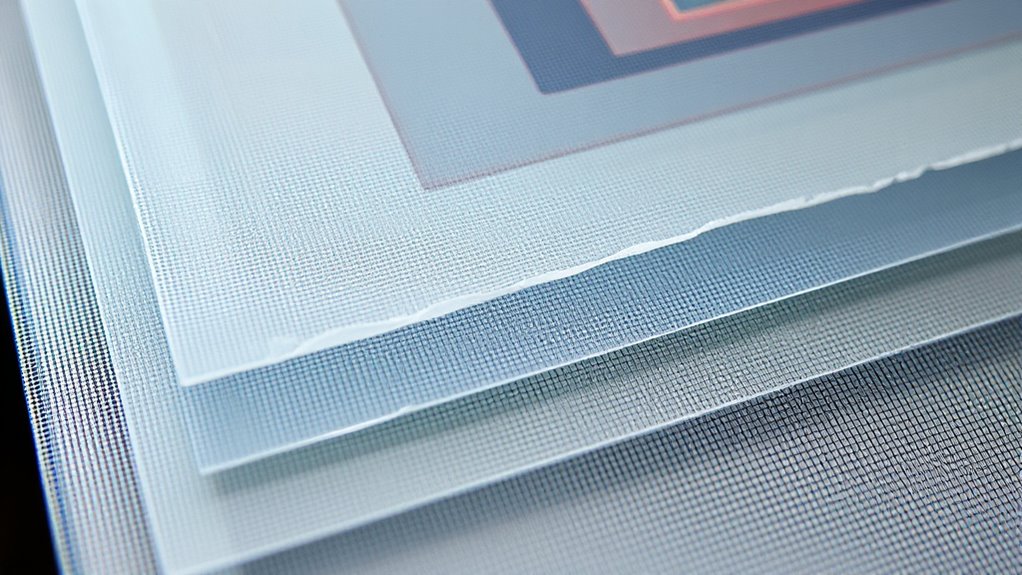

When you work with ink, controlling its opacity is essential; more opaque inks create bold, striking images, while less opaque inks offer subtlety. The screen mesh plays a key role here, as it determines how much ink passes through to create each layer. Additionally, energy-efficient manufacturing of screen components can influence the consistency and quality of your prints. A well-optimized manufacturing process ensures reliable layer consistency across multiple prints, which is vital for professional results.

A finer mesh allows for detailed, intricate layers, while a coarser mesh is better for bold, solid areas. By stacking multiple layers with varying ink opacities, you can produce rich, multidimensional prints that stand out. Understanding layer management is crucial for achieving precise results and avoiding issues like ink bleeding or misalignment.

Recognizing how layers interact helps you achieve professional, eye-catching results in screenprinting. Additionally, understanding the impact of contrast ratio on image quality can help you optimize your final print for better depth and clarity.

How Layers Add Depth and Detail to Your Designs

Layers are the key to creating depth and intricate detail in your screenprints. By stacking multiple layers, you can build shadow effects that give your design a sense of dimension and realism. Incorporating layer management techniques ensures each element is precisely placed, enhancing overall visual coherence. For example, using darker layers behind lighter ones helps shadows appear more natural, adding visual interest. Layers also allow you to enhance texture, making certain areas stand out with tactile quality. This technique can simulate rough, smooth, or patterned surfaces, enriching your overall design. When you carefully plan each layer, you control how light and shadow interact, giving your artwork depth and complexity. Understanding color theory can further improve how you combine layers for harmonious and striking results. Additionally, applying proper air purifier maintenance can help keep your workspace free of dust and airborne particles that might affect your tools or work environment. Regularly calibrating your airless paint sprayer ensures consistent application and prevents uneven layers, which is crucial for achieving professional results. Staying aware of financing options can also help you invest in quality equipment without overextending your budget. The result is a more engaging, professional-looking print that captures attention through subtle detail and textured richness. Layers truly elevate your screenprints beyond flat images into dynamic visual stories.

Why Layers Are Key to Color Accuracy and Vibrancy

Layers help you place colors precisely where they need to be, making your design sharp and vibrant. Overlap and blending of layers can enhance depth but also risk muddying colors if not managed carefully. Proper layer management ensures your final print maintains both clarity and brilliance. The order in which you layer inks considerably impacts the final look, affecting both color accuracy and overall vibrancy.

Precise Color Placement

Achieving vibrant and accurate colors in screenprinting depends heavily on placing each color precisely in its intended position. Accurate placement guarantees colors stay sharp, avoiding unwanted overlaps that can muddy the design.

When you position colors carefully, you enable better control over color blending, allowing subtle shifts or contrasts to come through clearly. Precise placement also influences texture creation; well-aligned layers can add depth and dimension, enhancing the overall visual impact.

Misaligned colors can result in blurry edges or unintended overlaps, diminishing vibrancy. By focusing on exact placement, you maintain the integrity of each color, ensuring that the final print looks clean, vivid, and true to your vision.

Proper positioning is essential for achieving professional, high-quality screenprints with maximum color impact.

Overlap and Blending

When you carefully position each color, you set the stage for effective overlap and blending, which are essential for vibrant, accurate prints. Layer overlap allows colors to blend smoothly, creating seamless progressions and richer tones.

Proper overlap ensures that colors mix naturally, enhancing depth and vibrancy without muddying the image. Avoid excessive overlap, which can cause colors to bleed or become less distinct, and too little, resulting in harsh edges.

By controlling how layers intersect, you improve color blending and achieve a more polished look. Remember, the goal is to balance layer overlap to maximize vibrancy while maintaining clarity.

Mastering this aspect of layering elevates your screenprints from basic to professional-quality, with true-to-life color accuracy and dynamic visual impact.

Layer Order Effects

The order in which you layer colors considerably impacts both the accuracy and vibrancy of your screenprint. Placing opaque inks first allows subsequent layers to stand out, ensuring bright, true-to-color results.

Conversely, layering lighter inks over darker ones can cause muddiness or dullness, reducing vibrancy. Ink opacity plays a pivotal role here: more opaque inks mask underlying colors better, while less opaque inks require careful placement.

Additionally, stencil complexity influences layer order; intricate stencils demand careful sequencing to prevent smudging or misregistration. Properly ordered layers help maintain sharpness and color integrity throughout the print.

How to Manage Multiple Layers for Clean, Precise Prints

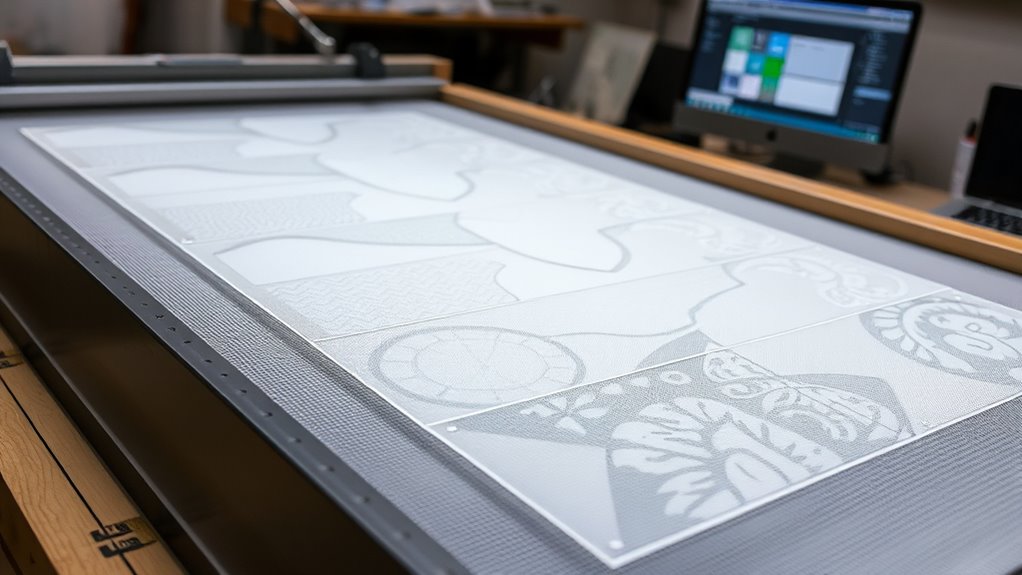

Managing multiple layers in screenprinting requires careful planning and organization to guarantee each color lines up perfectly. Start by designing your layers with clear separation, ensuring each element is on its own layer for easy management.

When applying ink, wait for it to dry completely before adding the next layer; this prevents smudging and misalignment. Properly curing each layer helps achieve sharp, clean edges and maintains color integrity, especially during color mixing.

Use registration marks or guides to keep layers aligned throughout the process. Keep your workspace tidy, and work systematically from the bottom to the top layer. This approach minimizes mistakes, ensures precise prints, and results in a professional finish every time.

How to Use Layering Techniques for Halftones and Gradients

Layering techniques are essential for creating smooth halftones and gradients in screenprinting, allowing you to produce subtle shading and tonal variations. To achieve this, use halftone techniques by varying dot sizes and spacing to simulate different shades. Incorporating layering techniques helps to build depth and dimension in your prints, making them more visually appealing. Gradients are best created through careful gradient blending, where overlapping semi-transparent layers transition seamlessly from one tone to another. Start with a light base layer and gradually add darker layers, adjusting opacity and dot density to refine the transition. Keep in mind that precise registration guarantees each layer aligns perfectly, preventing unwanted streaks or blotches. Experiment with different halftone patterns and layer overlaps to develop smooth, professional-looking gradients. These techniques give your images depth and dimension, elevating your screenprints beyond flat, two-tone designs.

Why Layer Order Matters for a Flawless Final Print

Understanding the importance of layer order is key to achieving a flawless final print in screenprinting. Layer sequencing determines how inks interact during ink layering, affecting the overall look and durability.

If you print the wrong order, colors may blend improperly, or details can get obscured. For example, printing a light color before a dark one can cause the lighter layer to be hidden or look uneven. Proper layer sequencing ensures each ink layer sits correctly and bonds well, preventing issues like smudging or bleeding.

When you plan your layers carefully, you control how the inks build upon each other, resulting in sharp, vibrant images. Remember, the sequence isn’t just about aesthetics—it also impacts the print’s longevity. Vibe coding techniques can help streamline this process by offering innovative ways to plan and visualize layer arrangements.

Mastering layer order is essential for a professional, flawless final result.

How to Troubleshoot Common Layering Problems

When your layers aren’t aligning properly, start by checking registration accuracy to guarantee each layer lines up perfectly. If the ink looks inconsistent or uneven, adjusting the ink viscosity can make a big difference. Finally, improve screen tension to keep your stencil stable and prevent smudges or misprints. Additionally, monitoring lighting conditions can help ensure accurate registration and consistent ink application during the printing process. Being aware of cookie categories and how they affect your browsing can also help in troubleshooting online resources or tutorials related to screenprinting. For optimal results, it’s also helpful to understand how layering techniques influence overall print quality and how proper setup adjustments can prevent common issues. Regularly checking your equipment calibration ensures that all your adjustments lead to consistent and professional prints.

Check Registration Accuracy

To guarantee your design lines up perfectly during screenprinting, it’s vital to verify registration accuracy before printing each layer. Misaligned layers can ruin your final product, so check that the registration accuracy ensures perfect color alignment. Visualize your workspace:

| Layer 1 | Layer 2 | Layer 3 |

|---|---|---|

| Base design | Second color | Final details |

| Slight shift | Perfect match | Slight misalignment |

| Clear registration | Overlap issues | Precise layering |

| Correct position | Misregisters | Accurate overlay |

Ensure each screen is aligned with the previous. Use registration marks and check under good lighting. Adjust as needed before printing. Consistent registration accuracy guarantees sharp, professional results and prevents costly mistakes. Understanding dark psychology tactics can also help you recognize and avoid manipulation during collaborative projects or in competitive environments. Additionally, regularly reviewing your screen setup and maintaining equipment can improve overall registration consistency. Regularly inspecting your registration process helps identify potential issues early and maintain high-quality results, just like calibrating a telescope mount for precise tracking in astrophotography. Incorporating quality control methods into your workflow can further enhance your registration accuracy and overall print quality.

Adjust Ink Consistency

If your ink isn’t the right consistency, layering problems like bleeding, uneven coverage, or dull colors can occur during screenprinting. To fix this, check your ink viscosity; it should be smooth and flow easily without being too thick or runny. Accurate measurements of viscosity can help ensure proper consistency. If the ink is too thick, thin it with the appropriate reducer, but avoid over-diluting. Proper mixing techniques are essential to maintain uniformity, as inconsistent emulsion can cause ink to seep or layer poorly. Additionally, using the right filtering methods can prevent debris from affecting your layers. Consistent ink properties are crucial for achieving predictable and clean layering results. Regularly monitoring emulsion consistency can help maintain quality and prevent layering issues. Maintaining proper layering techniques and ensuring your equipment is calibrated can also contribute to better results. Keep test prints handy to gauge adjustments quickly. By maintaining correct ink viscosity and emulsion consistency, you’ll achieve cleaner, more consistent layers that enhance your overall print quality.

Improve Screen Tension

Have you checked your screen tension lately? Low or uneven tension can lead to blurry prints and inconsistent layers. To improve screen tension, first make sure your frame is properly tightened and free of warps. Proper tension helps maintain emulsion thickness during exposure, preventing pinholes and detail loss.

If your tension is too loose, the emulsion may sag, causing ink bleed or uneven layers. Conversely, excessive tension can cause the frame to warp or crack. Regularly test tension with a tension meter or by tapping the frame—if it sounds dull, it needs tightening.

Also, check your emulsion thickness; a consistent, well-applied emulsion relies on proper tension to cure evenly. Keeping your screen taut ensures sharp, accurate images and smoother layering overall.

Digital vs. Manual Layering: Tools and Best Practices

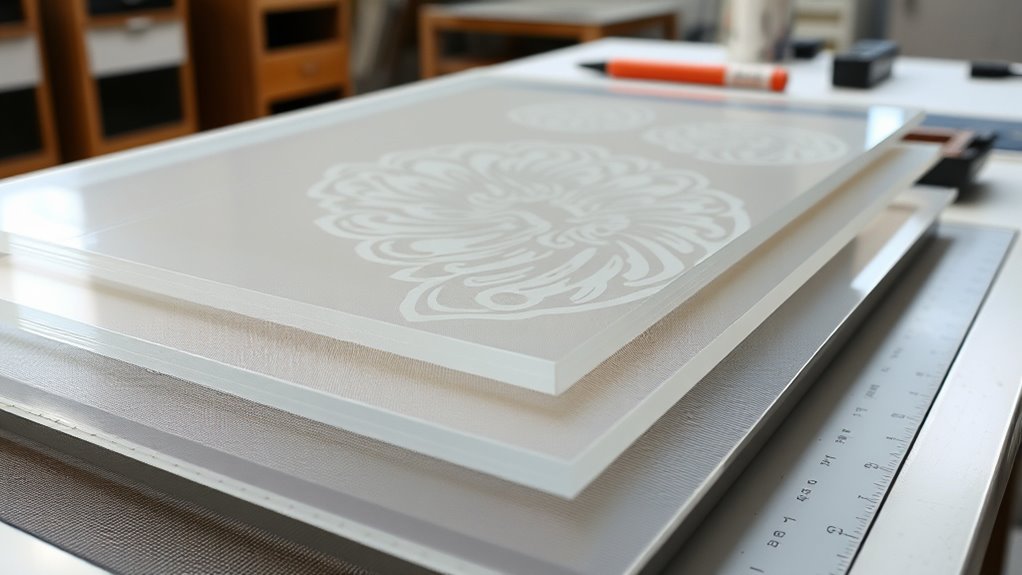

Digital and manual layering each have distinct tools and techniques that influence the quality and efficiency of your screenprints. Digital layering uses software like Photoshop or Illustrator to create precise, easily adjustable layers. It allows you to experiment with colors, transparency, and details before printing, reducing errors.

Manual layering involves physically applying stencils, screens, or masks to build each color or element. This process demands patience and skill but offers hands-on control and a tactile feel. Best practices for digital layering include organizing your files clearly and working with high-resolution images.

For manual layering, ensure your screens are properly prepared and aligned. Both approaches require attention to detail, but choosing the right method depends on your project’s complexity, your skill level, and your desired outcome.

Benefits of Mastering Layering for Faster, Consistent Prints

Mastering layering techniques substantially boosts both the speed and consistency of your screenprints. When you refine your layering skills, you can achieve smoother color blending and cleaner stencil creation, reducing errors and reprints. Efficient layering minimizes setup time, allowing you to produce multiple prints quickly with uniform results. Consistent application of each layer assures accurate color blending, giving your prints a professional look. To visualize the benefits:

| Benefit | Explanation |

|---|---|

| Faster Production | Less time spent correcting mistakes |

| Improved Consistency | Uniform results across prints |

| Better Color Blending | Seamless transitions between layers |

| Precise Stencil Creation | Clean, sharp designs with minimal cleanup |

| Reduced Waste | Less ink and material waste due to fewer reprints |

Mastery in layering elevates your workflow, making each print faster and more reliable.

Frequently Asked Questions

How Do I Choose the Right Number of Layers for My Design?

To choose the right number of layers for your design, consider its complexity—more intricate designs usually need additional layers for detail and color separation.

Start simple if you’re a beginner, then add layers gradually as needed.

Evaluate how many colors and details your design requires, balancing clarity with efficiency.

Can Layering Techniques Be Used for Specialty Inks?

Yes, layering techniques work well with specialty inks, allowing you to manipulate ink opacity and create unique texture effects.

By applying multiple layers of different specialty inks, you can achieve richer colors or subtle textures that stand out.

You’ll want to carefully plan your layers to guarantee each ink’s properties enhance your design, giving it depth and dimension without overloading the print.

This approach unlocks creative possibilities with specialty inks.

What Are the Best Practices for Cleaning Between Layers?

To guarantee proper ink adhesion between layers, you should clean your screen thoroughly with a good degreaser or emulsion remover before switching inks.

Use a squeegee with appropriate pressure—not too heavy—to avoid ink buildup or smudging. Rinse the screen well and dry it completely.

This prevents cross-contamination, maintains sharp details, and makes certain each layer adheres properly for a professional finish in your multi-layered print.

How Do I Prevent Color Bleeding When Stacking Layers?

To prevent color bleeding when stacking layers, guarantee proper ink adhesion by applying each layer evenly and allowing adequate drying time.

Use precise stencil overlap, aligning each layer carefully to avoid unintended mixing. You can also slightly offset each layer or use a transparent base layer.

Are Digital Layering Tools Compatible With Manual Screenprinting Processes?

Digital layering tools can be compatible with manual screenprinting if you adapt them properly. You’ll want to focus on digital compatibility, ensuring your software can create clear, precise layer separations that translate well to screenprinting.

Then, with manual adaptation, you can transfer these designs onto screens accurately. This approach helps you combine digital precision with traditional methods, making your process more efficient and your results more consistent.

Conclusion

Mastering layers in screenprinting is essential for creating vibrant, detailed, and professional-looking prints. By understanding how to manage and layer your designs effectively, you’ll achieve better color accuracy, depth, and precision. Practice proper layering techniques, troubleshoot issues promptly, and explore both digital and manual tools to enhance your skills. The more you master layers, the faster and more consistent your prints will become, elevating your overall screenprinting game.